The rigorous demands of many process operations require reliable and accurate analytical measurement devices. There are various types of technologies that can handle some of the most difficult process conditions for analytical measurement. Both liquid and gas analysis instrumentation are necessary in today’s challenging processes. Safety, reliability and performance are key components in selecting the right product for your applications.

Conductivity meters, analyzers and transmitters are used for continuous process measurement and monitoring of conductivity, resistivity, WIFI, demineralizer water, RO water, percent concentration, boiler blowdown and TDS.

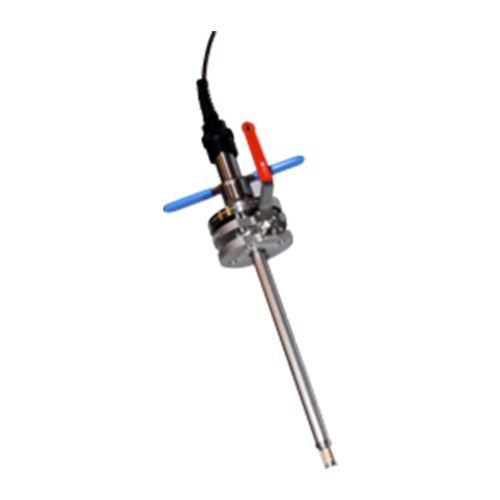

Conductivity sensors and electrodes are used to measure process conductivity, resistivity, WIFI, demineralizer water, RO water, percent concentration, boiler blowdown and TDS. Various installation options including retractable, flow thru, immersion, and direct insertion. Proper electrode/sensor selection is critical for optimal measurement results.

Dissolved oxygen (DO) is a liquid process measurement for determining the amount of oxygen dissolved or carried in the process liquid. There are three common technologies for dissolved oxygen measurements: polographic, galvanic and optical. The standard units of measure are milligrams per liter (mg/l), parts per million (ppm), parts per billion (ppb), or % saturation.

Dissolved Oxygen (DO) electrodes and sensors are the sensing portions of a DO measurement. There are three common technologies for dissolved oxygen measurements: polographic, galvanic and optical. Various installation options including floating ball, retractable, flow thru, immersion, and direct insertion.

Caustic soda (sodium hydroxide) is an important basic material in the chemical industry and is mainly produced by the electrolysis of soda. There are two types of electrolysis processes: the diaphragm method and the ion-exchange membrane method; the latter is becoming mainstream because of its lower energy consumption and higher product quality. Both methods involve evaporating the solution after the electrolysis process to make concentrated caustic soda.

pH and ORP meters, analyzers and transmitters are used for continuous process monitoring of pH and ORP to ensure water/product quality, monitor effluent discharge, batch neutralization, pulp stock, scrubbers, cooling towers, chemical, water/wastewater treatment and many other applications.

pH electrodes and sensors are the sensing portions of a pH measurement. Various installation options including retractable, flow thru, immersion, and direct insertion. Proper pH electrode/sensor selection is critical for optimal measurement results.

Digital or SMART sensors maintain specific measurement and calibration data on an integrated chip along that is an integral part of the sensor. This data can be exchanged between the sensor and either a process transmitter or a laboratory PC.

The Yokogawa turbidimeter uses a pressurized head tank to eliminate air bubbles, which are a major error factor in the measurement of low turbidity levels. The TB750G turbidimeter continuously measures post-filtration turbidity in order to achieve the required turbidity control value of 0.1 mg/l.